AS/NZS 1554.1 Compliance Requirements

April 2014Hi, are you a steel fabricator or site welding business? If so, are you aware of your obligations to the end client, the job contract, the drawings and specifications? This is a greatly misunderstood area and we would love to help you manage it.

Firstly all structural engineers specify the Australian Standard AS/NZS 1554.1 or AS/NZS 1554.5 on their standards and on their drawings. What does this mean for you the fabricator or the site welder? Well these standards are created to make sure all parties have a foundation, a level playing field, to work on as an absolute minimum guarantee of a certain level of quality. It lays out the requirements for design, as in weld size, length and placement, for the minimum training level required, do you need a full tradesman or not, for the testing required, x-ray or crack testing, and for the documentation that you are required to produce to satisfy the job requirements.

Let’s cover these items one at a time.

Design requirements

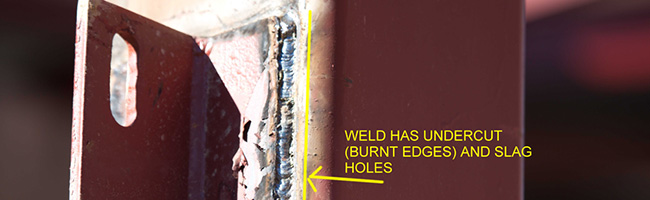

Is the construction AS/NZS 1554.1 or .5? Generally most work is specified as AS/NZS 1554.1 SP. Occasionally, in high stress or fatigue situations AS/NZS 1554.5 will be specified. This is usually carnival equipment or structures like the Southern Star Observation Wheel in Melbourne. The rating SP compared with GP concerns weld quality and how it is inspected. It addresses weld defects such as cracks, undersize, undercut and porosity for example. SP rating is much more stringent. SP category requires more NDT, non destructive testing, such as X-ray or ultrasound than does GP. SP category requires a higher level of testing on weld procedures and welder qualifications.

Training requirements

AS/NZS 1554.1 requires the use of certified tradesmen. This is NOT an indentured tradesman with Cert 2 or 3. It is a tradesmen that has been tested to the weld procedures being used in the last 6 months via a welding supervisor witnessed test approved by a NATA laboratory. Most work in the structural trade is fillet welding. Some of it is performed in the vertical position. The welding operator must be tested for the type and position of weld to be used. A simple mock up fillet weld in 10mm plate, witness and tested will allow a welder to weld on the job for the next 6 months. This applies to the welding performed in the factory and on site.

Testing and inspection requirements

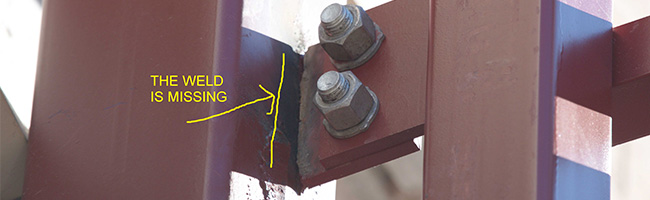

Under AS/NZS 1554.1 all welding must be subjected to some inspection. This applies to work fabricated in the factory and on site. The selection of GP or SP category by the engineer is what drives the level of inspection. Using a W.T.I.A. accredited Welding Supervisor will make all this very streamlined for your firm. He will determine what level of testing is needed and what percentage must be assessed with that method. Generally everything is visually scanned for gross defects and missing welds then a closer visual inspection is carried out on a percentage of the work. NDT such as x-ray or magnetic particle testing will follow to pick up small defects the eye cannot see. Inspection of welding is your best defense against mistakes and defects. Records of all testing must be kept on file and presented to the client at the end of the job.

Documentation required

All welding and fabrication work must be performed using qualified procedures. The simplest level of procedures is the SWMS system. This applies to each task being performed such as drilling, cutting or welding. More critical to the job and to quality is the formulation of a qualified welding procedure specification, a WPS. This is a document setting out all the settings to be used by the welding operator. This ensures no matter who does the welding it is done correctly. Welder qualification records, WQR’s, prove the staff have been tested to weld adequately to the provided WPS. NDT records prove that all of the job has been tested with the correct test and to the appropriate percentage level. Any repairs that arise must also be documented and records kept.

With the assistance of a W.T.I.A. Welding Supervisor all of these tasks will be performed seamlessly and will result in your firm actually saving money owing to lower rework levels. All of this quality system can be sued as a fantastically powerful sales tool to your potential clients as many other firms are non-compliant.

Global Welding Technology

18 Roseman Road

Chirnside Park. Vic. 3116.

Tel: (03) 9017 6593

Mobile: 0425 751 609

Email: Please use our contacts page